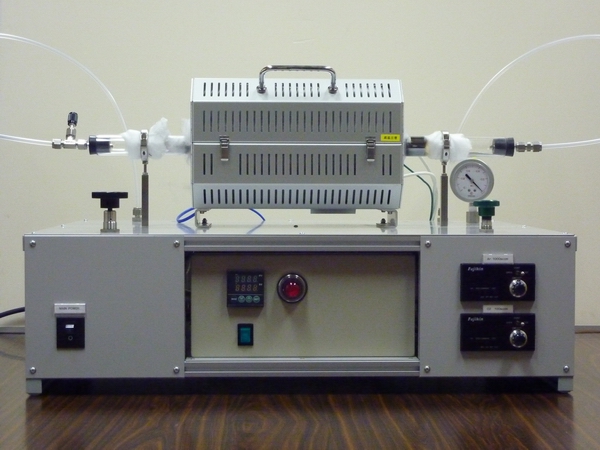

Zinc Oxide Nano-rod Synthesis System

MPCVD-ZnO

Easy synthesis of Nano wires of ZnO

*Appearance and specifications are subject to change without notice.

| Purpose: | A furnace type of thermal CVD system for the formation of ZnO nanorods on substrates. |

|---|---|

| Features: |

|

This is a thermal CVD system for synthesizing zinc oxide nanorods with a horizontal quartz tube furnace (diameter = 30mm).

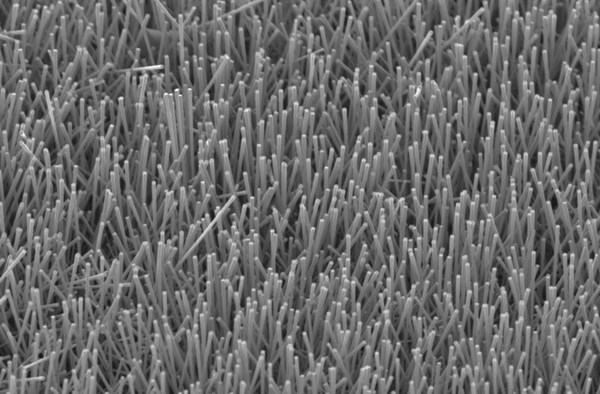

This system adopts a mechanism to grow vertically-aligned ZnO nanorods on a substrate while vaporizing Zn in an atmosphere containing oxygen. A substrate (usually sapphire and silicon) and zinc material are placed inside the furnace, and inert gas and oxygen gas are injected from the gas controllers. Vertically aligned zinc oxide nanorods will be grown on the substrate in a few minutes. Microphase developed its own CVD process and made it possible to have only a few minutes of reaction time (the shortest in the world).

Since the growth speed of zinc oxide crystal is very fast in the direction of the C-axis, zinc oxide tends to grow in rod and whisker shapes. Growing vertically aligned ZnO nanorods on a substrate usually requires the substrate to be made of a single crystal, and its lattice spacing needs to be extremely close to the lattice spacing of zinc oxide on the C-plane (either sapphire or GaN substrate). Alternatively, an Au catalyst film must be formed on the substrate; Au particles act catalysts in the Vapor-Liquid-Solid (VLS) growth mechanism.

In our unique growth process, Zn itself acts as the catalysts in the VLS growth mechanism.

As a favor, this system can form vertically aligned ZnO nanorods on silicon and quartz substrates,

in addition to sapphire substrates, without an Au catalyst film.

1-step ZnO nanorods

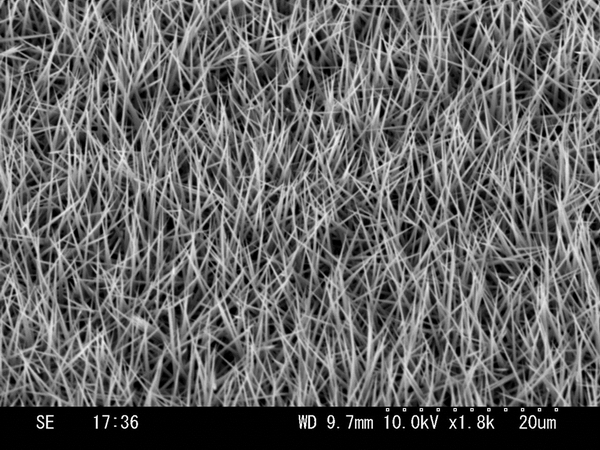

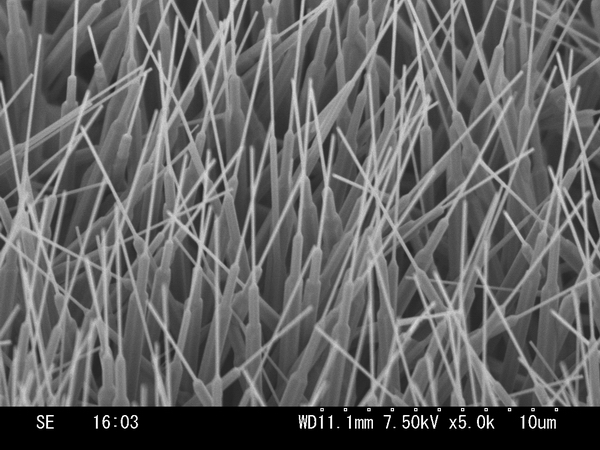

ZnO nanowhiskers

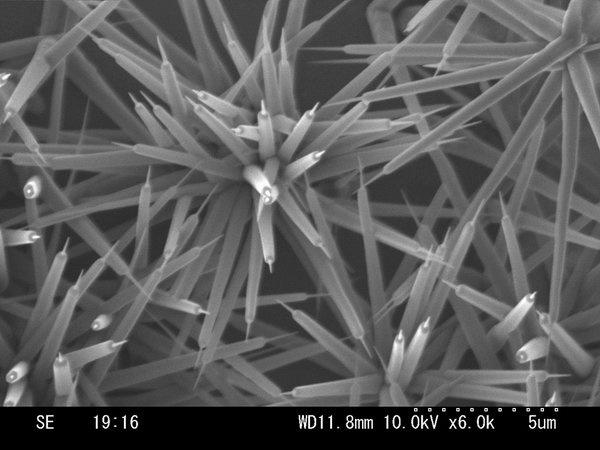

2-step ZnO nanorods

3-step ZnO nanorods

Specifications

| Configuration | Tubular Furnace | Operating Temp. | 400~1000℃ |

| Control of Temperature | 1zone Program Control | ||

| Dimension | W300㎜×H200㎜×D186㎜ | ||

| Electric Capacitance | 500W | ||

| Furnace Tube | Material | Quartz | |

| Dimension | OD30㎜×ID26㎜×L750㎜ | ||

| Control of Gases | Gas Flowmeter | ||

| Introduced Gases | Carrier Gas:N2 or Ar

Oxidation Gas:O2 |

||

| Vacuum Gauge | Bourdon Gauge | ||

| Vacuum Pump | Oil-sealed Rotary Vacuum Pump | ||

| Dimension | W156㎜×H200㎜×D300㎜ | ||

| Quartz Boat | |||

| Dimension | W900㎜×H600㎜×D500㎜ | ||