Thermal CVD System for CNT & Graphene Synthesis

MPCVD-Graphene

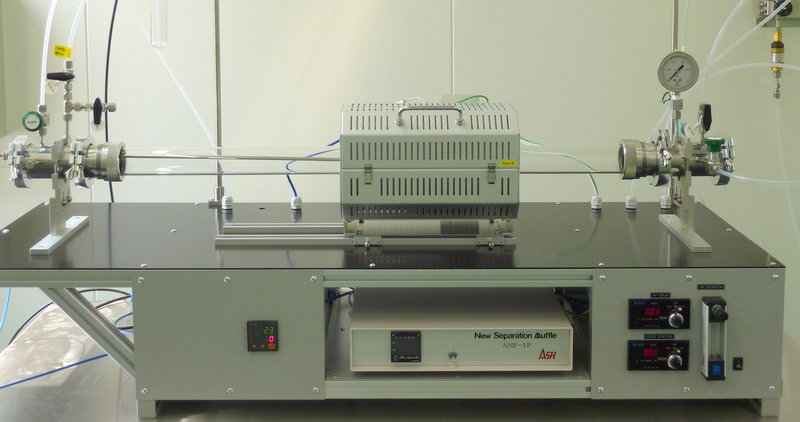

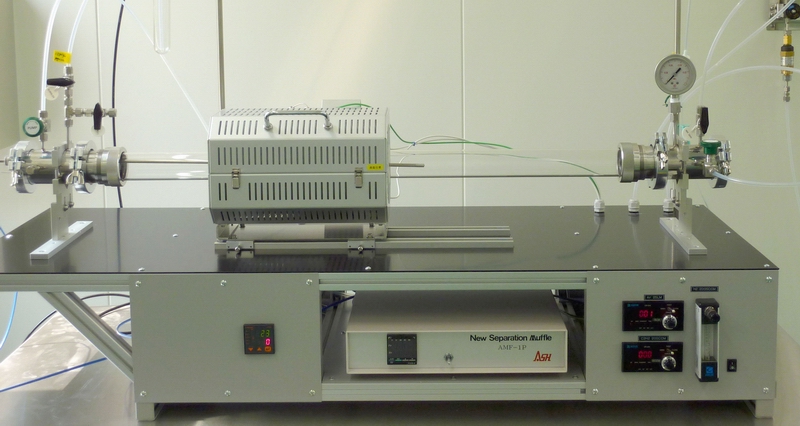

Rapid heating & cooling by furnace-sliding

Sample-heating (before sliding hot-zone of furnace)

Sample-cooling (after sliding hot-zone of furnace)

*Appearance and specifications are subject to change without notice.

| Outline: | A furnace type of thermal CVD system, equipped with a rapid heating/cooling mechanism based on quickly sliding furnace out of the hot zone, is designed for researchers go grow graphene films on substrates (Ni or Cu foils), and also CNT forests or CNT powder. |

|---|---|

| Features: |

|

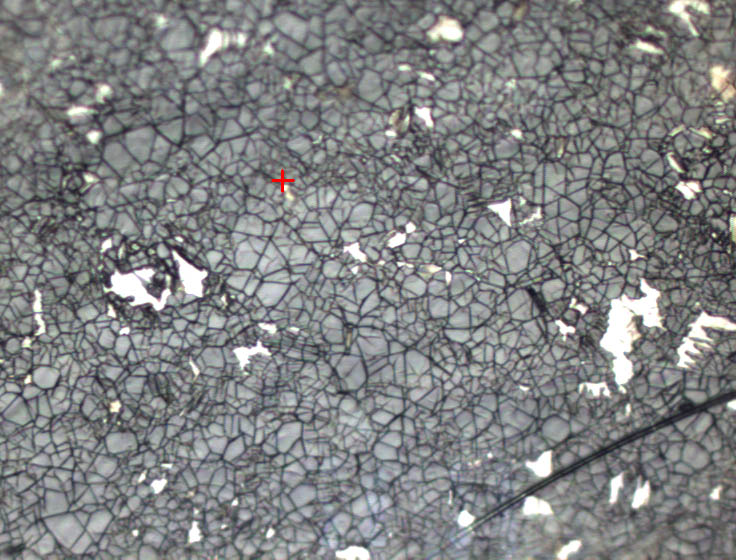

Single-layer graphene/Ni optical microscope image formed with high vacuum exhaust system

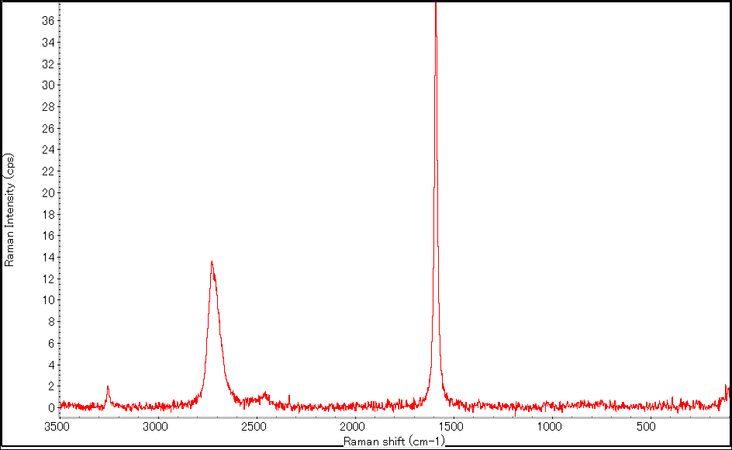

This is a special thermal CVD system for synthesizing graphene films with a horizontal quartz tube furnace (diameter = 50mmφ). A catalyst substrate (usually Cu foil) is placed inside the furnace, and methane gas or acetylene gas is injected from the outside at a low flow rate and low pressure to form a graphene film on the catalyst foils.

It has been known that the cooling speed is a key factor for forming high-quality graphene films. Rapid cooling suppresses the excess deposition of carbon from the catalytic metal foils (such as Cu or Ni foils).

This system is equipped with a rapid cooling mechanism. The tube furnace slides 30 cm sideways to the reaction tube, and the hot zone of the furnace can be moved away from the sample. Shifting the hot zone rapidly cools the sample. This system realizes an extremely rapid cooling effect with a simple mechanism.

Single-layer graphene/Ni SEM image formed with high vacuum exhaust system

Specifications

| Configuration | Tubular Furnace | Operating Temp. | 400~1000℃ |

| Heating length | L250㎜ | ||

| Control of Temperature | 1zone Program Control | ||

| Dimension | W300㎜×H200㎜×D186㎜ | ||

| Electric Capacitance | 700W | ||

| Furnace Tube | Material | Quartz | |

| Dimension | OD50㎜×ID46㎜×L1200㎜ | ||

| Control of Gases | Mass Flow Controller | ||

| Introduced Gases |

Carrier Gas:N2 or Ar Reducing Gas:H2 Hydrocarbon Gas:C2H2 or C2H4 or CH4 |

||

| Vacuum Gauge | Bourdon Gauge | ||

| Vacuum Pump | Oil-sealed Rotary Vacuum Pump | ||

| Feed Mechanism for Liquid Fuel(Option) | |||

| Measuring Thermocouple into Furnace Tube(Option) | |||

| Slide Mechanism for rapid cooling(Sliding Width:250㎜) | |||

| Dimension | W1400㎜×H1000㎜×D500㎜ | ||