CUSTOMIZED EQUIPMENT

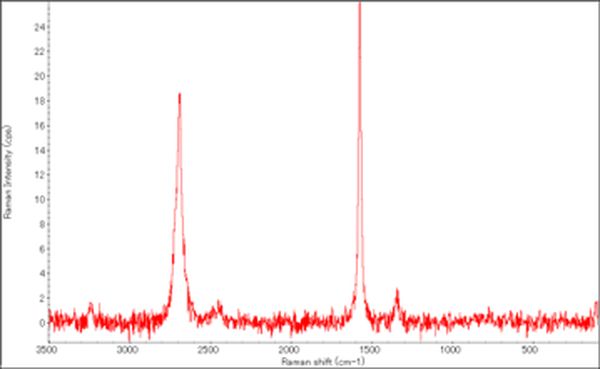

RF Plasma CVD System

| Overview: | RF plasma sputter apparatus was modified so that resolutions of ammonia gas or hydrocarbon gas can be accelerated and nitrogen-doped carbon film can be deposited on substrates. |

|---|---|

| Characteristic: |

|

CVD System with Solid Precursor Unit

| Overview: | A solid-precursor introduction unit was added at the upper stream of our standard CVD system [MPCVD series]. Sublimed vapors of metallic compounds or oxides can be introduced in to CVD reaction zone for reaction and film deposition. |

|---|---|

| Characteristic: |

|

CVD System with Liquid Precursor Unit

| Overview: | A liquid-precursor introduction unit was added at the upper stream of our standard CVD system [MPCVD series]. Vapor of metallic compounds or oxides bubbled by carrier gas can be introduced in to CVD reaction zone for reaction and film deposition. |

|---|---|

| Characteristic: |

|

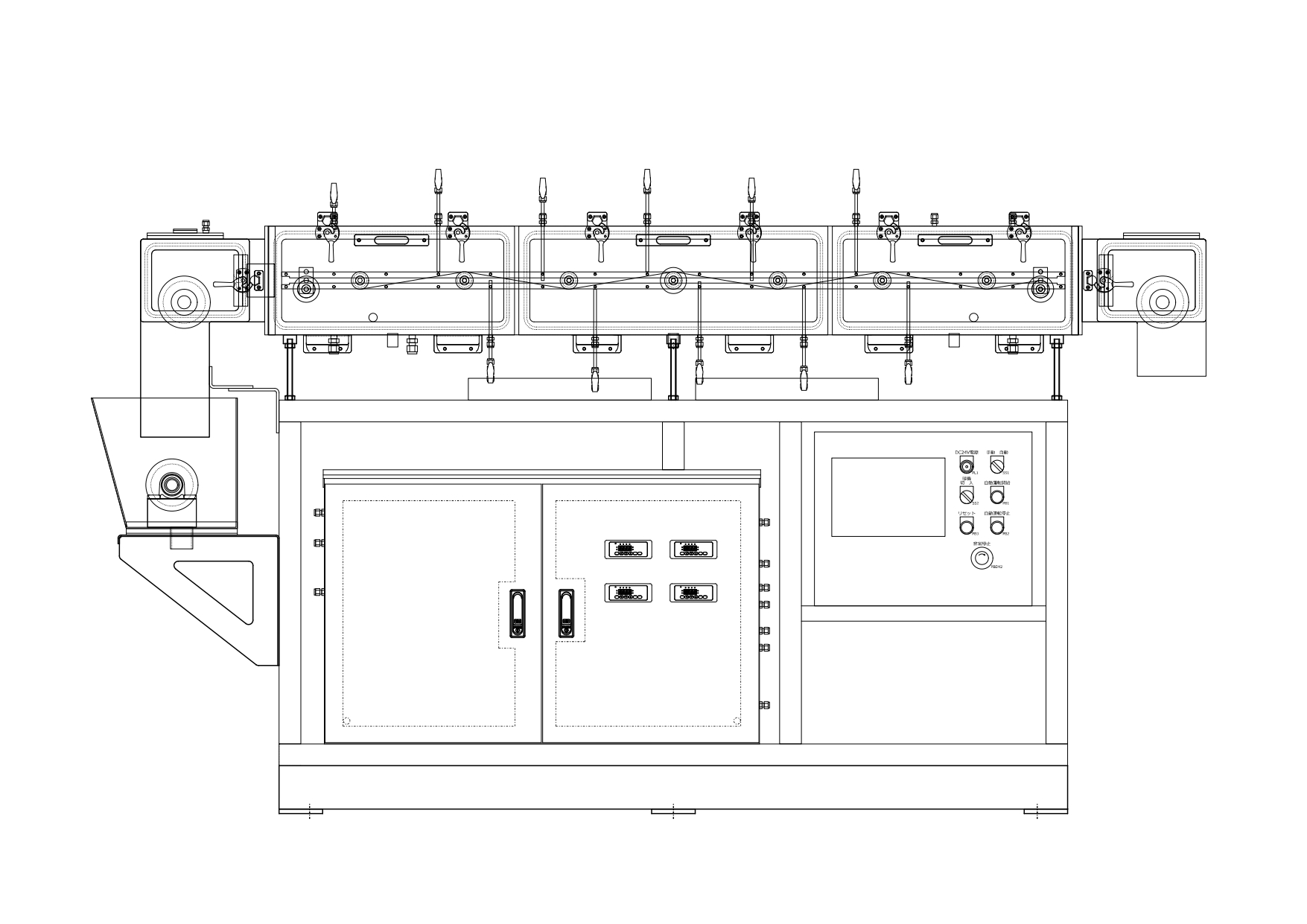

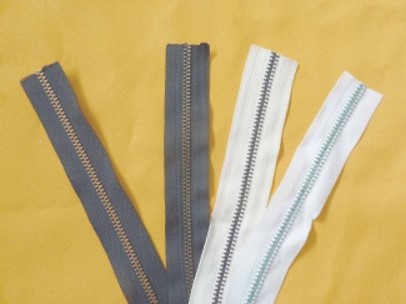

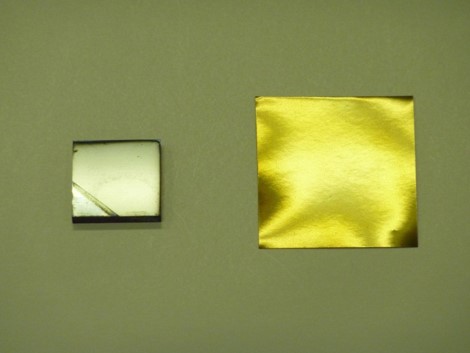

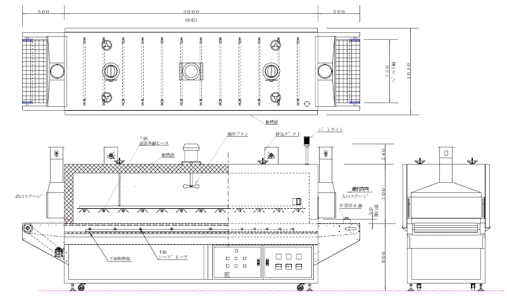

Roll-to-Roll Low-Temperature CVD System for Tarnishing Copper Alloy Fasteners

| Overview: | We have successfully established an atmosphere-pressure, room-temperature, roll-to-roll CVD processes for tarnishing copper-alloy fasteners and changing the colors of such fasteners. A high through―put and large-size apparatus for continuous CVD treatment of fasteners was fabricated for mass-production. |

|---|---|

| Characteristic: |

|

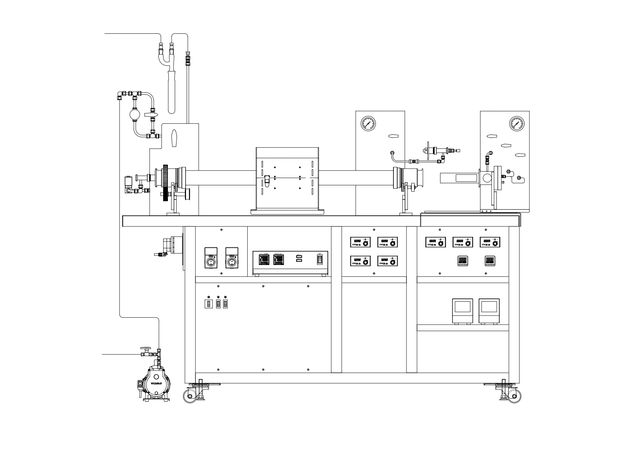

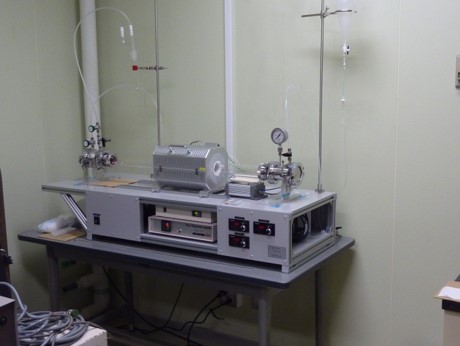

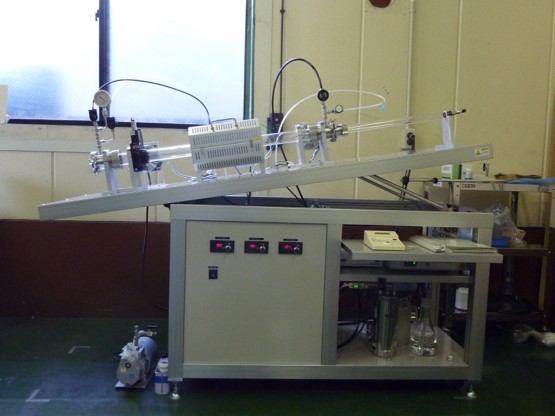

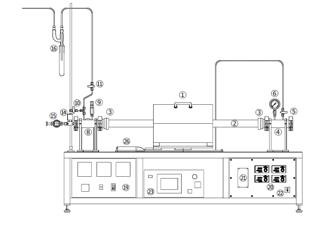

Furnace-Sliding CVD System for Continuous CNT Forest Synthesis

| Overview: | Long-quartz-tube and furnace-sliding CVD system was fabricated for continuously growing vertically-aligned CNT forests on Zr or Cu foils, which are used as thermal conduction TIM (Thermal Interface Material) devices. |

|---|---|

| Characteristic: |

|

Rotary-kiln CVD System for Continuous CNT powder Production

| Overview: | This is a continuous CVD system for growing powder CNTs continuously. Tiltable and rotatable quartz tube is equipped, so that the catalyst powders are feed through the hot zone from upper stream in a constant velocity, and CNTs are synthesized in the hot zone are collected at the bottom stream. |

|---|---|

| Characteristic: |

|

Continuous CVD System for Coating Carbon Films on WC Powder

| Overview: | A CVD system was fabricated for coating carbon films on WC powder to improve the toughness of WC molds. |

|---|---|

| Characteristic: |

|

Desk-Top Examination System for Carbonization and Activation of Biomass Materials

| Overview: | Desk-top CVD system was modified for carbonizing biomass materials and then activating the carbonized product with steam. It will be useful in laboratory for R&D in the field of recycle of biomass materials. |

|---|---|

| Characteristic: |

|

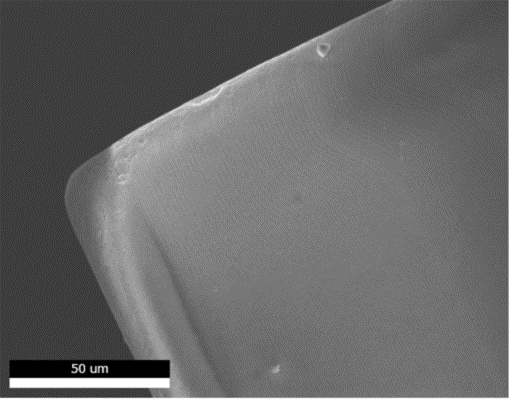

High-Vacuum & Full Automatic CVD System for Graphene Synthesis

| Overview: | Our CVD system for graphene synthesis was modified by adding a powerful turbo molecular pump and full automatic operation system. As the result, graphene films having high crystalline quality were grown on Ni or Cu foils. |

|---|---|

| Characteristic: |

|

Desk-Top Hot-Filament CVD System for Diamond Synthesis

| Overview: | A hot-filament system is added to our MPCNT-Basic, to allow us to synthesize diamond films on a substrate by using ethanol fuel. |

|---|---|

| Characteristic: |

|

Desk-Top Nitriding Treatment System

| Overview: | Our desk-top CVD system [MPCNT-Basic] was modified by adding ammonia introduction unit to realize nitrogen doping treatment |

|---|---|

| Characteristic: |

|

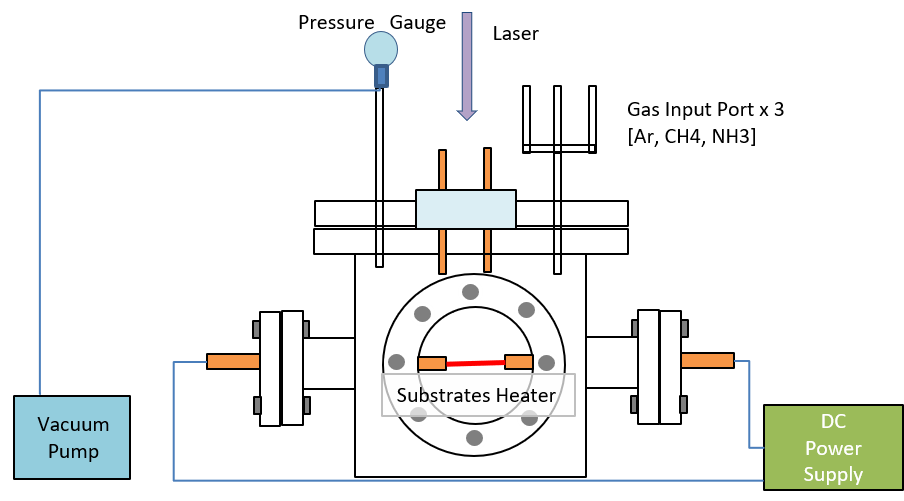

Laser-Assisted CVD Chamber for Film Deposition

| Overview: | A vacuum chamber with a special window for transmission of UV laser beam was fabricated for the use of laser-assist CVD. NH3 and C2H3 gas flow meters were quipped, allowing us to deposit nitrogen-carbon compound, which will show photocatalytic effect. |

|---|---|

| Characteristic: |

|

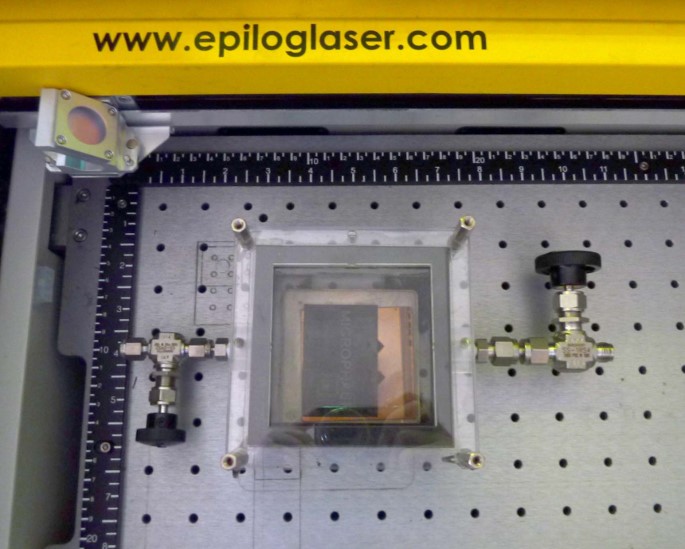

Reaction Chamber for Surface-Treatment by Laser-Beam

| Overview: | Our originally designed sample chamber was fabricated, in which sample to be laser-treated is placed and different gases can be introduced through valves, and then laser beam is transmit through the special window glass designed for the fiber laser beam. This sample chamber can be used in commercial fiber laser engraving machines. |

|---|---|

| Please contact us for details. |

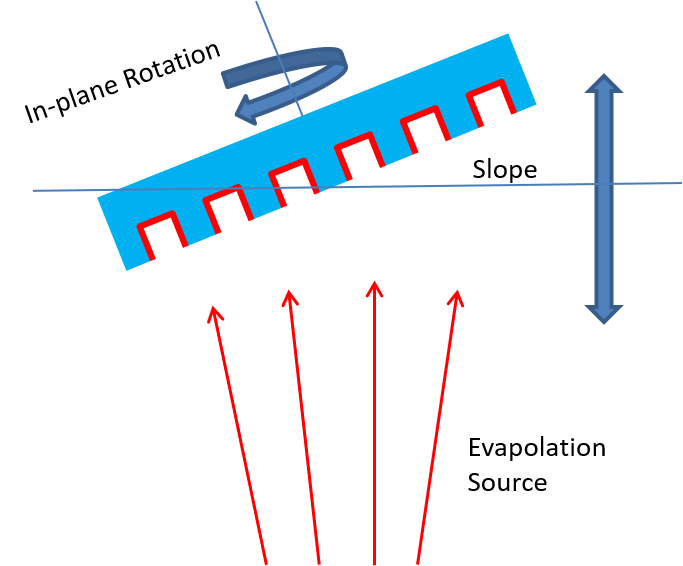

Sample Holder with 2-Axis Rotations for Vacuum Vapor Deposition

| Overview: | Our product of MPVAP was modified for depositing metal films on samples having a complicated and microscopic 3D structure, such as CNT forests, micro flow channels. For this purpose, the sample substrate was tiltable and rotatable, as shown in the following figure. Because of the two-axis rotations, deposition at deep valleys of microscopic structure can be achieved. |

|---|

Sample Vibrating Unit for Deposition Metals on Powder Samples

| Overview: | We can deposit metal films on powder materials by loading a sample-vibrating unit and heating a down-direction vaporization crucible. We will fabricate a special such unit, which can be attached to your own vacuum vapor deposition apparatus for metal film depositions on powder materials. |

|---|---|

| Characteristic: |

|

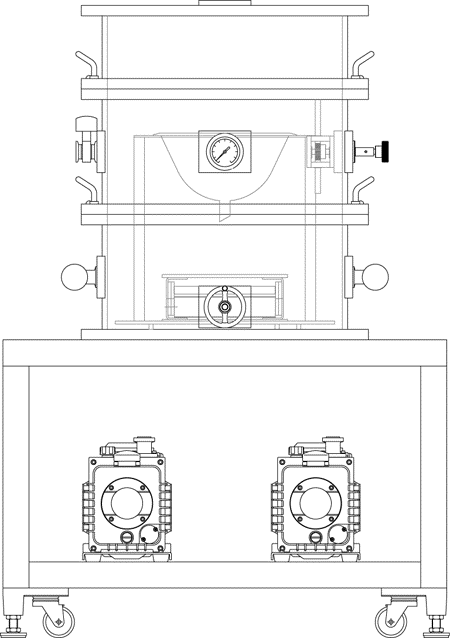

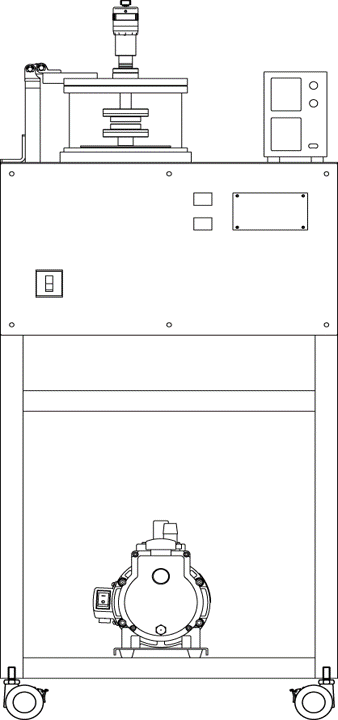

Vacuum Device for Defoaming and Molding of High-Insulate Silicone Rubbers

| Overview: | This vacuum device was designed for removing air bubbles in high-insulate silicone liquid mixed with curing agent,

and for filling the liquid into a mold containing X-ray emission electrodes,

and then making a bubble-free mold to insulate these electrodes from atmosphere. Separated 3-step transparent acrylic chambers and 2 powerful rotary pumps, and lifting mold table were prepared. |

|---|

Large-Size Equipment for Mass-Production of Barrel Polishing Media

| Overview: | Plastic barrel media for polishing metal parts are formed by dispersing polishing agents into plastic solutions and then curing and molding. A large-scale equipment for mass-production of such media was fabricated, which including mixing process, defoaming process, filling process, and curing process. |

|---|---|

| For detail information, please contact us. |

Evaluation Apparatus of Field-Emission Property of CNT Emitters

| Overview: | A characterization apparatus for easily measuring the field emission property of CNT emitters was fabricated. |

|---|---|

| Characteristic: |

|

Gas-Analysis Apparatus with Q-Mass elements

| Overview: | Q-mass analysis system was arranged for detecting generated gases from biomass materials during their carbonization process. CH4, H2, CO, CO2, etc. can be detected. |

|---|---|

| For detail information, please contact us. |

Interference-Fringe Analysis Software for High-precision Phase Detection in Electron-Holography

| Overview: | The major works of our company are related materials. However, we have also rich knowledge in the field of electron holography and optical interferometry,

and in the field of scientific computations and numerical calculations. We have developed an image analysis and numerical calculation program, by which phase image can be precisely extracted from its interference fringe pattern. This program has been used by several scientists for their researches in electron holography. |

|---|---|

| For detail information, please contact us. |